Cold Rooms

Store your perishable products for longer periods, and in larger quantities with our Cold Rooms. Thesecan be customizedfor specific needs. These Cold Rooms are well insulated, highly efficient andmeticulously designed to cater to a wide temperature rangefrom +15 and-25 ◦C.Talk to us about your requirements and we promise to deliver global solutions at local prices.

Description

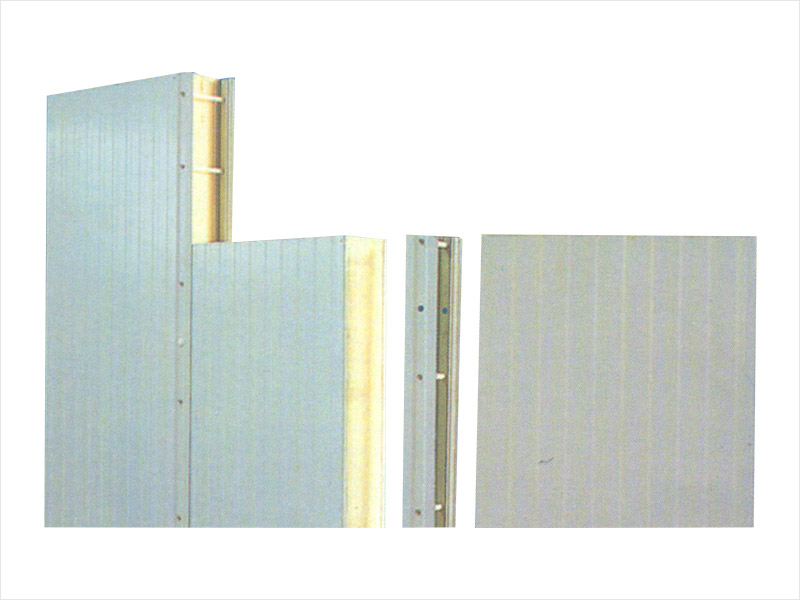

- Polfrost branded Cold Rooms are indigenous in design.

- Turnkey Cool and Cold Room Solutions, right from Conceptualization, Heat-Load Calculations, Design of Structural Panels as well as Thermal Control Systems and CA systems, Manufacturing to Commissioning and Installation.

- In house production of panels, complete from Decoiling Units to CNC Turret Press and Bends for the sheet metal requirements of the Cold Rooms.

- Polfrost Cold Room Panels are lightweight and have a good strength to weight ratio.

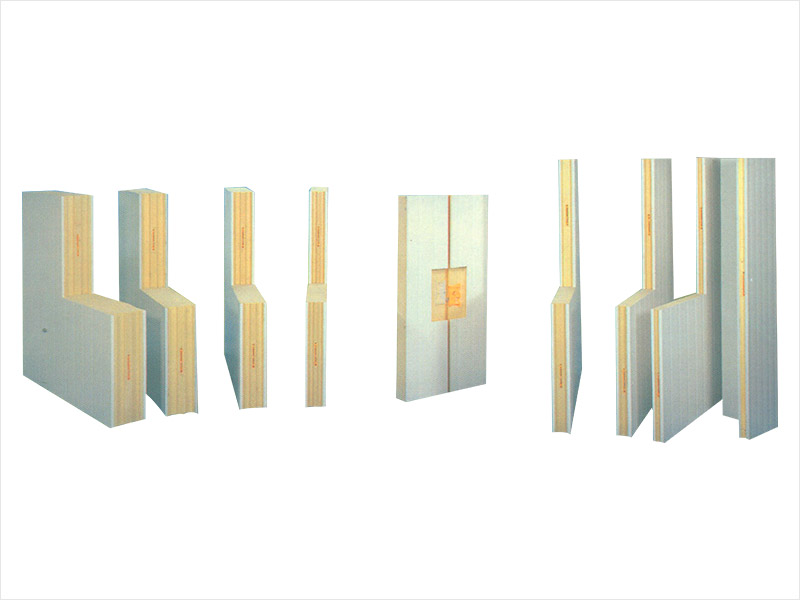

- Complete sealing of air gaps in the Cold Room panel joining system by use of tongue and groove interlocking system, doubly ensured air tightness by cam locking system.

- Easy and quick assembling and disassembling of the structural PUF panels due to the Cam Locking system, establishing complete Modular Cold Rooms and Pre-Fab structural requirements.

- Imported PUF forming chemicals from BASF and Dow, implying uniform PU density. This helps in maintaining uniform temperature throughout the Cold Room zones minimizing the possibilities of temperature leaks.

- PU Panels to suit every application including Clean rooms, Cold Rooms, CA Chambers, Food and Beverage Storage Applications, Long Storage Applications and Fruit Ripening Chambers.

- Design and Construction of Walk-In Cold Rooms/Cool Rooms/Chambers.

- Exhaustive range of Door Systems, such as Flush Doors, Swing Doors, Sliding Doors – Manual and Automated, Commercial Doors, Temperature Retardant Glass Doors, Fire Doors, Hangar Doors, Acoustic Doors, Double Leaf Hinged and Sliding Doors, etc.

- Thermal Breaks at door sections reducing Thermal Losses at junctions as well as via conduction, using High grade FRP sections.

- Specialized Door systems, customized to suit customer requirements, with Dorma, Kasan, Castle cold room door hardware.

- Walk-able ceilings and Custom made PU floorings complete with Tar felt and in-situ construction.

- Wide variety of skins to choose from, such as SS, GIPP (Galvanized Iron Pre-Painted), GIPC (Galvanized Iron Powder Coated), with different choice of thickneses from 0.45mm to 1.2mm.

- Aluminum and PVC Coving to suit the corners and restrict contamination.

- PIR Panels for fire retarding structures and Rockwool Panels, manufactured on request.

- Special skins available on request such as PVC Coated Steels, for specialized applications like Medical sector clean rooms, Clean rooms, Operation Theatres, CA Chambers, etc.

Specifications

| Physical Properties | Unit | Average Measured Value | Physical Properties |

|---|---|---|---|

| Density Of Foam | KG/M3 | 40 ±5% | DIN 53 420 |

| Thermal Conductivity | BTU/I2/F/°INCH | 13 ±2% | ASTMC 177 |

| Thermal Conductivity | W/KM | 0.022 | DIN 52612 |

| Closed Cells | % | 94 | ISO DP 2246 |

| Compressive Strength | KG/CM2 | 2.1 | ASTM D 1621 |

| Compressive Strength | N/MM2 | 0.20 | DIN 53 421 |

| Compression | % | 10 | DIN 53 421 |

| Flexural Strength | N/MM2 | 0.30 | DIN 53 432 |

| Bending | MM | 10 | DIN 53 423 |

| Flammability (No Dripping or Melting) | - | - | ASTM 16 92 - 74 CLASS SE |

| Extent of Burn | - | Self Extinguishing | BS-4735 |

| Dimensional Stability C | % | 10 | Length & Width Tested at -180° C to 100° C for 48 hr. at 90% relative humidity |

| At - 25° C | % | 0.1% | - |

| At + 38° C | % | 0.1% | - |

| At + 90° C | % | 0.4% | - |

| Temperature Range | °C | -180° C To 100° C | - |

| Water Absorbtion | % | 2% | At Max 98% RH |

| Water Vapour Permeability | ng/PASM | 5.5 | S-11239 |

Range

Polfrost Cool and Cold Room come in the following specifications as per requirements

|

|

||||||

|

|

||||||

|

|